In the tech field, success is built on the pillars of innovation. Whether designing industrial machinery or retail electronics, the need to improve remains a constant. For most manufacturers, this means that the R&D department needs to make new prototypes regularly, finding new ways to meet customer needs.

However, it should come as no surprise that the majority of prototypes never make it to market. What happens to these ideas, and why do they get culled so early?

Prototyping gives manufacturers a means to subject their product ideas to extensive testing, both in the laboratory and in the real world. In many cases, the end result is that the product doesn’t meet expectations and needs to be reworked.

Thomas Edison famously asserted that when it came to the light bulb, he had not failed, he just found 10,000 ways that wouldn’t work. Even now, more than a century later, the original design of that product continues to be improved for greater energy efficiency, lower production cost and other important benefits.

However, the creation of a working prototype proved the most important elements of Edison’s invention. Every one of those failed tests was a step on the way to success.

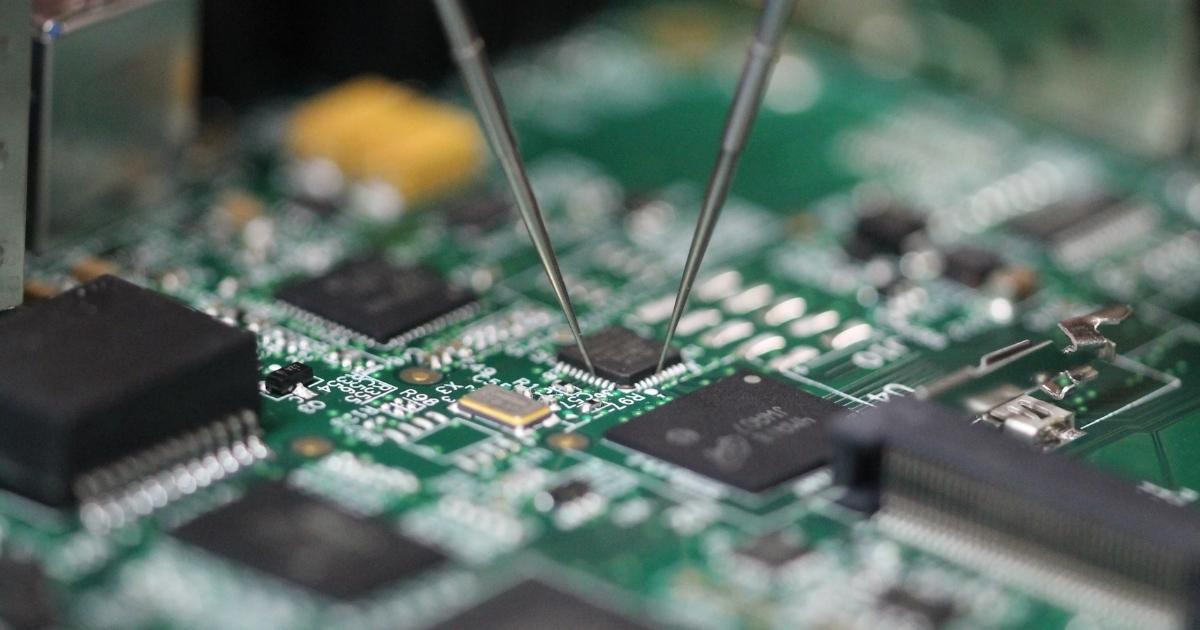

When it comes to printed circuit boards, major manufacturers follow a similar pattern. In order to put their innovative product ideas to test, they need to hire fast, responsive PCB manufacturers. By taking a rough initial sketch and designing a working prototype circuit board, innovative product functionality can be tested extensively before being brought to market.

Some of the most important considerations to keep in mind when choosing a prototype manufacturer are:

Once you have high quality prototypes to work with, there are additional obstacles between your new product and the open market. The main obstacle to keep in mind is the cost of high-volume production. Manufacturers in industries with higher production volumes, such as retail electronics, often encounter this obstacle as a make-it-or-break-it scenario.

Production costs for prototypes are typically minimal, since design and detail are the main points of focus. Once a project is cleared for high-volume production though, costs can soar if material concerns were not handled appropriately at the design stage.

We specialize in producing high quality prototype circuit boards. Once we finish the job, our clients typically take their proprietary designs overseas for mass production, where highly automated and competitive wages offer a clear commercial advantage. However, the companies responsible for mass production are very limited by the scope of the designs they receive from us—if certain resources aren’t readily available, they’re forced to compromise.

Resources readily available in Silicon Valley might not enjoy the same degree of accessibility in South Asia, for example, and this places strain on manufacturers. When manufacturers are compelled to continue, they can find themselves forced to raise prices far beyond any reasonable market expectation.

One of the most relevant real-world cases where miscommunication between prototype and production led to skyrocketing prices is the Google Glass. The company’s ambitions led to it releasing an “early adopter” version of the product for $1500—the actual retail price never materialized.

Why did it cost so much? Unrestrained, exotic design combined with considerable man-hours led to a need for materials that were not readily available when production began. This led to expensive setbacks and compromises that could only be recuperated by raising the price.

Not every company is as well-positioned to recover from failures as Google is, but we are all equally capable of learning from its mistakes. With more than two decades of experience building printed circuit boards, Power Design Services can advise on potential mass

For more information, visit www.greencircuits.com.