These guidelines give the assembly team a standardized, no-nonsense method to produce a reliable panelization solution. By eliminating panelization guesswork, you ensure successful assembly even for complex projects.

One of the principal decisions made during panelization is whether break-routing or scoring (v-cut) will be used to separate the individual circuits from the array. Green Circuits has the equipment needed to accommodate the needs of clients who choose either method. The following guidelines help ensure projects get completed on-time and in accordance with our high standards of quality.

Routed panels are ideal for PCB board arrays featuring irregular shapes. Under such conditions, the v-cut process can’t be trusted to produce reliable results. However, it is even more important to adhere to proper panelization guidelines for irregular boards.

PCB designers need to keep a few important physical considerations in mind for route and retain panelization projects. For one, panel arrays that crowd too many PCBs into a large array have a tendency to bend or sag when held horizontally. This can create numerous assembly problems, but is easily remedied by remembering to put a priority on panel stability.

One of the simplest ways to ensure a stable board is to avoid cramming too many PCBs onto a single array. We specify a maximum array size of 8 inches x 10 inches, which is usually sufficient to avoid mechanical accidents and damage when each PCB tab occupies 2 linear inches of board length.

We specify a 0.5-inch tooling rail for these types of projects. While you could theoretically fit more PCBs in the same space by reducing the size of the rail, array stability suffers as a result. Assuming a cutter width of 0.079-inches cutting twice from the clearance material, 0.158 inches of material can be discounted from the panel strength equation.

We also specify a 0.1-inch board spacing for route and retain arrays for the same reason. Ultimately, the need for a stable board that responds favorably to handling and assembly is far more valuable than being able to fit more tabs on an array.

It might seem like a lot of extra material, but the board will lose strength with every tab that’s broken out during assembly. Knowing that break-out tabs need to be placed on both the X and Y axis of the board, it’s easy to see how an array can become increasingly weak as it goes through the assembly process.

This, along with the need for tooling rails to contain fiducials and tooling holes, is why we ask our clients to respect our 0.5-inch tooling rail guideline.

We specify non-plated tooling holes of 0.125 inches in diameter for both break-route and v-cut arrays. By using non-plated tooling holes, we ensure that the mounting location of the board does not affect the functioning of its electrical components — non-plated holes are isolated.

Individual tabs should have four additional holes located outside the fabrication line of the PCB as well. These holes need to be centered within the tab and have a diameter of 0.02 inches. Centering ensures the most reliable break, even though it can leave side board protrusions. Be sure not to place breakaway tabs under overhanging components, if any exist.

When considering placement for tab perforations, it’s important to keep all of the perforations along a single break axis and extending that break axis to the very edge of the array. Otherwise, the process of applying upward pressure to the break axis will also apply a perpendicular force to the adjacent, non-collinear perforations — possibly damaging the board or entire array in the process.

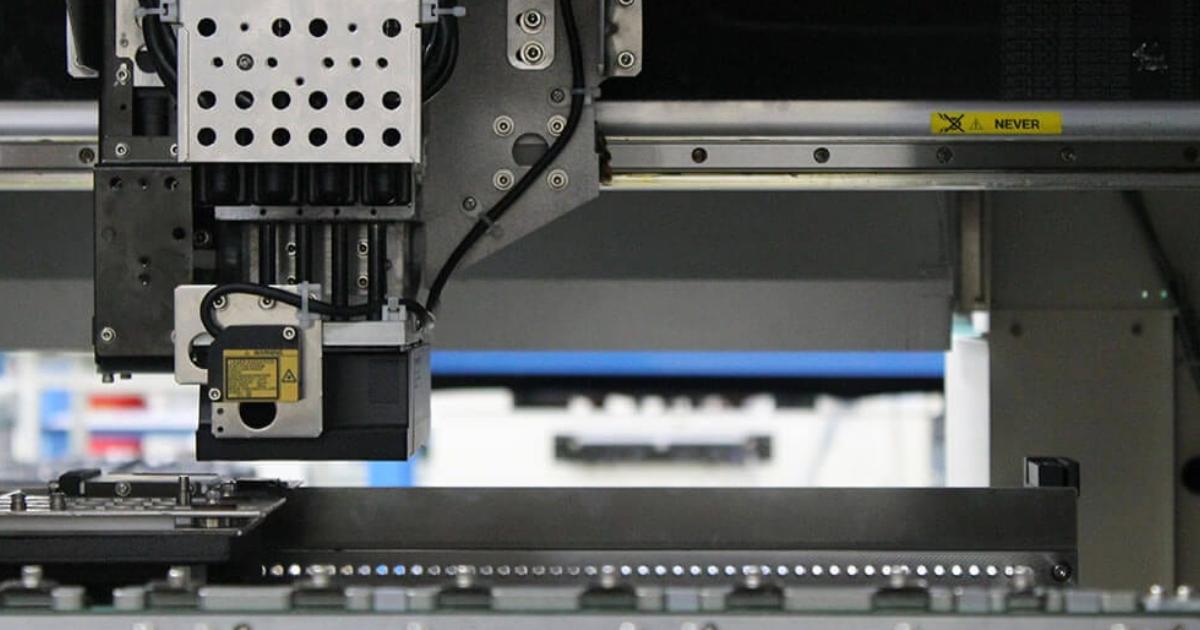

When it comes to fiducials, Green Circuits specifies 0.031-inch etchings with a 0.250-inch pad clearance. Edges of fiducial marks need this clearance, because marks placed too close to the array edge may get obscured by the conveyor top clamps used by processing machines that use camera systems for fiducial alignment. And of course, don’t forget that individual boards within the array also need fiducial marks.

For more information, visit www.greencircuits.com.