When designing innovative products, material concerns often take a backseat to user experience goals. This is natural – after all, good products that offer value to end-users are essentially guaranteed a place on the modern tech marketplace. However, material management concerns take priority when considering the cost and turnaround time of product manufacture.

Whether designing retail electronics or heavy industrial machinery, clients always want cheaper prices whenever possible. While we never compromise on the quality of the work we do at Power Design Services, we do achieve savings through effective material management.

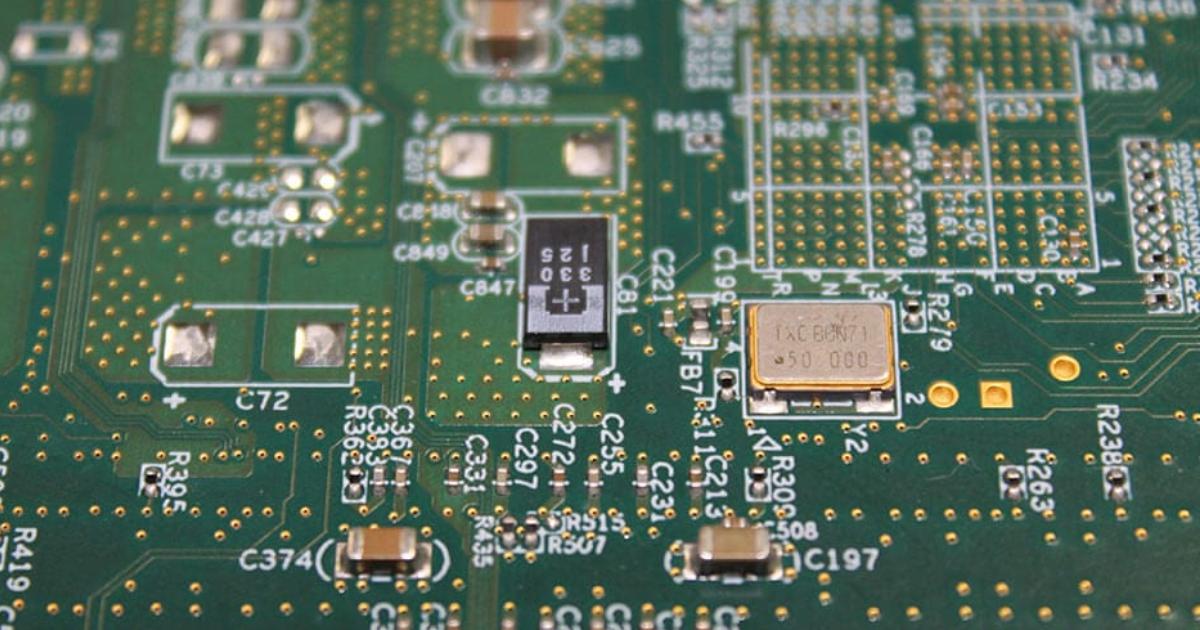

One of the major obstacles that printed circuit board manufacturers run into is finding inexpensive sources for high quality components and materials. The material used to create a printed circuit board is extremely important – brittle, poor quality board substrate can crack during assembly, ruining entire batches of PCBs.

We have a dedicated purchasing department that looks for reliable indicators of quality when sourcing components, and prioritizes the most efficient option each time.

Here are some of the factors we take into consideration when sourcing printed circuit board substrate:

A high transition temperature protects the resulting PCB from barrel cracking. It also protects against pad fracture during soldering.

Certain assembly processes expose boards’ wiring assemblies to temperature shocks. Materials that expand in response to heat may generate defects or other problems after manufacture. This is a particular problem when PCB designers use multiple dual-layer substrates – each one can expand at a slightly different rate, inducing uneven levels of stress.

The tendency of an insulating material to absorb arc energy from an electromagnetic field passing through it. This value should be low for circuit boards designed for radio wave applications.

By carefully screening source materials through these and other factors, we’re able to guarantee the quality of the resulting boards.

With clear and objective criteria for the materials we use, our purchasing department has a free hand to find the least expensive avenues for procuring those materials.

By taking logistics and economy of scale into account, we’re able to calculate the total unit price of our PCBs with precision. This lets our team make informed decisions about which supplier offers us – and by extension, our clients – the best possible price.

Where most PCB assemblers go wrong is treating procurement as a tactical process rather than a strategic one. Many PCB companies in our industry under-optimize their supply chain because they source components and materials on an as-needed basis.

The Green Circuits way of doing things is more strategic – we’re able to predict future needs for certain materials based on our work history and track record. That data lets us craft procurement strategies that keep our inventories well stocked for future orders, decreasing prices and turnaround times across the board.

Green Circuits is a printed circuit board manufacturer based in San Jose, CA. We design, build, and assemble prototype PCBs for clients in a wide variety of industries, from wearable tech to heavy machinery. Get a quote on your assembly project today!

For more information, visit www.greencircuits.com.