Few things are more exciting to manufacturers than new product ideas. New designs, engineering challenges and the ability to deliver a new user experience are all rewarding hallmarks of innovation. However, the road that separates conceptualization and commercialization is riddled with tight turns and obstacles. Fast, efficient prototyping is one of the best ways to prepare yourself for the journey.

Instead of being considered just one of many steps towards realizing a particular market goal, consider prototyping a unique asset that provides benefits no other part of the innovation process can. Companies that develop prototype

frequently and test them extensively are better prepared to meet the challenges of tomorrow’s technological environment than their competitors are.

Keep reading to find out exactly how early, frequent prototyping affects your bottom line:

All innovation includes a risk of failure—that risk is simply part of the process. Knowing that this possibility exists, it behooves innovators and manufacturers to mitigate its effects by failing early and cheaply.

Even the best ideas can turn out to be impractical, unfeasible or simply impossible. Prototyping offers one of the most effective ways to determine if that’s the case before investing a great deal of resources into the project. Failure is not something to be afraid of, but something that offers valuable feedback on how certain goals can and cannot be reached.

One of the main reasons innovative manufacturing project costs can spiral out of control is due to not fully understanding project requirements. Traditionally, retailers and other companies rely on focus groups and interviews to gather information on their planned products’ requirements. This doesn’t always produce relevant results, however, because it asks participants to conceptualize products that don’t exist.

On the other hand, when you offer focus group participants actual working prototypes of the products in design, you are far more likely to get detailed feedback that includes the additional requirements you’re looking for. Since you’re going to need to produce prototypes for late-stage focus group sessions anyways, simply moving this priority up a few notches is a sensible move that can yield valuable insight early on.

Time only enhances your ability to understand the problems your products are designed to address. If you or your design team has ever thought “If only we could go back in time and implement that feature…” you know the feeling well.

Building a functional prototype early in the development process forces you to address unforeseen technical challenges and develop a more elegant solution to the issue at hand. When this is done early, it gives you time to make changes and adjustments before product release actually occurs.

If your electronics manufacturing company is like most, it allows for spirited debate on engineering and design practice. The more qualified your engineering team’s members are, the more likely they are to have strong opinions on how certain features should be implemented. This inevitably leads to conflicts, which although stressful, are indicators of a healthy design process.

Prototyping is one of the most certain ways to resolve design conflicts of this type, since it allows for user-centric analysis and performance benchmarking. Not only does this save time otherwise spent on conjecture and theory, but it also helps the team make the correct design decision.

If your company plans on relying on outside investment, having access to a range of product prototypes is invaluable. Investors, like everyone else outside of an engineering or R&D department, have difficulty conceptualizing products they can’t see, touch or otherwise interact with. Combined with the additional scrutiny with which venture capitalists typically address start-ups, prototyping can be the only way to effectively demonstrate your idea’s feasibility.

The same can be said of stakeholders under a traditional corporate structure. This is especially true when executive-level decisions are made by a group of individuals without a background in engineering. To get a project green lighted, you have to show it works.

Although U.S. inventors need not present a working prototype of an invention to obtain a patent (this rule was struck from the record in 1880), it is still the safest way to demonstrate reduction to practice. This term is intentionally vague, and if a competitor is developing an idea similar to enough to yours, it could reasonably argue that you’re infringing on patent laws if your patent application relies only on schematics.

A prototype can conveniently sidestep this issue, potentially saving your intellectual property rights from infringement in a costly legal battle.

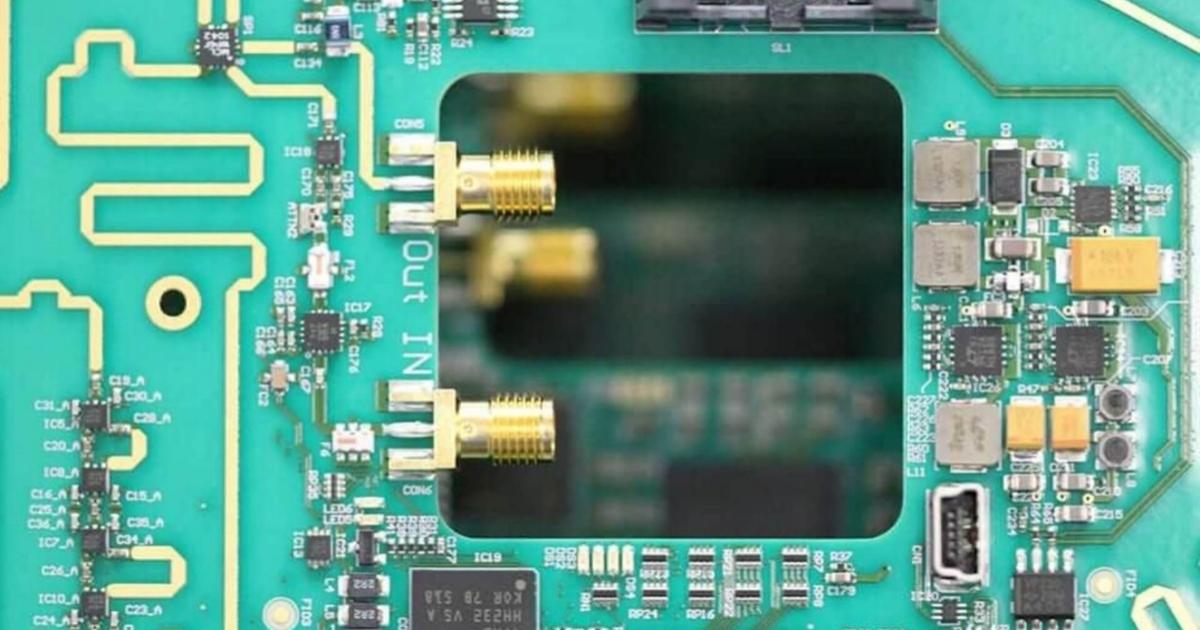

Green Circuits manufactures printed circuit boards for manufacturers in a broad range of industries, including retail electronics. We offer quick turnarounds and highly active customer service, ensuring that you get the most out of your prototypes as quickly as possible. Contact us by calling 408-526-1700 and ask for a prototype assembly quote today.

For more information, visit www.greencircuits.com.