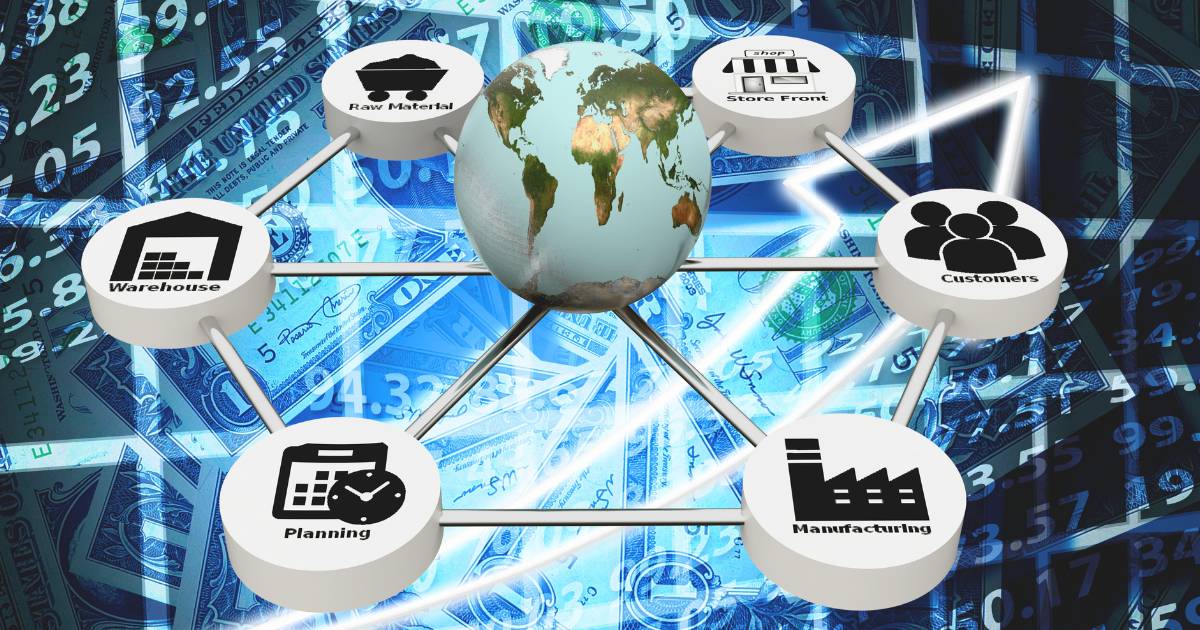

End-to-end PCB assembly solutions from an established company can significantly shorten your supply chain and help you reach customers in a quicker and more cost-effective way. Studies show that concerted efforts can yield savings of $2 million to $10 million every year, depending on the size of your operations. While all manufacturers understand the economic value of smart supply chain management (SCM), most struggle to achieve efficiency. Successful SCM strategies center on meeting customer needs quickly and at the lowest possible cost. The simplest way to do this is by integrating all the variables in your production and distribution processes.

Let us look at the electronics industry where manufacturing defects and the consequent rework accounts for higher cost, market delays and loss of market share. Many manufacturers have learned the hard way that timely and cost-effective PCB design-assembly is critical to successful supply chain management. Since circuit board development is complicated, your choice of the PCB assembly partner will have a big impact on your success.

Simply put, long-term product quality and reliability as well as cost-efficiency cannot be achieved without the right circuit board manufacturing partner.

Without a doubt, faster prototyping means quicker product development which in turn increases your competitive edge. Reducing your PCB build and test time by half can make a significant difference. Sophisticated solutions from Power Design Services have made this dream a reality for our customers.Here are 3 distinguishing factors that have enabled us to reduce prototype and PCB assembly time for customers by 50%.

With supply chain management becoming a key differentiating factor, every company is racing to get the right product to the right place at the right time and cost. Working with Green Circuits will save you time and money. Our turnkey electronic assembly solutions are the preferred choice of engineering and manufacturing companies across the country. Our experienced team handles every aspect of your project—including PCB design, fabrication and electronic assembly in-house.

For more information, visit www.greencircuits.com.