One of the first steps to determining how to approach your IC reworking project is identifying costs and likely outcomes. Damaged PCBs can span the range from exhibiting almost unnoticeable malfunctions to near-complete physical destruction. Just like patients in a hospital, proper diagnosis is key to predicting how the recovery process will go – there is a world of difference between treating a headache and a heart attack.

The key to making this decision is determining what went wrong with the circuit in question. Environmental issues such as unexpected condensation build-up can sometimes be resolved simply. However, if the damage is extensive, then outsourced IC repair may be your only option.

Examine your needs and determine how closely you need the finished, repaired PCB to duplicate the physical characteristics of the original. How much variance can you tolerate? Most electrical issues – resistance, inductance, capacitance, cross talk, and frequency – require specialized expertise and equipment to address.

When considering the cost of reworking a PCB, you must also take into consideration the skill level of the engineer performing the work. PCB repair personnel cannot be part-timers who rotate repair duties alongside traditional PCB assembly responsibilities.

Manufacturers who try this almost universally fail because PCB repair skills are far more involved and more specific than assembly skills. There are far more steps involved in any repair operation than in most typical assembly procedures.

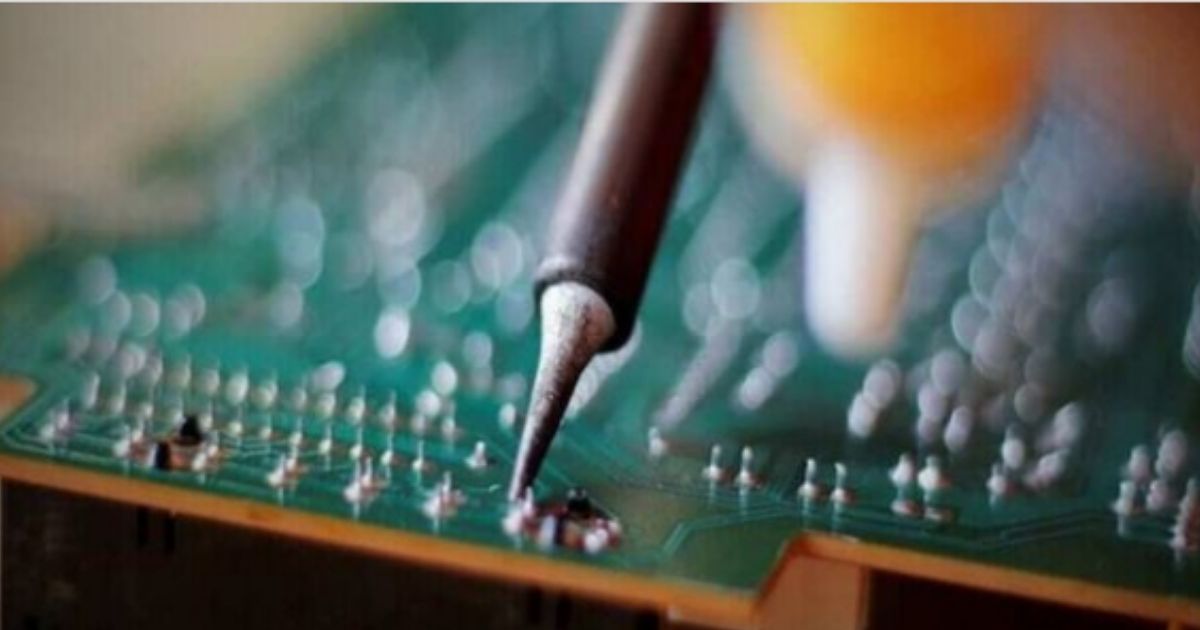

Beyond relatively simple conductor repair with epoxy seals or surface wires, it is likely that any advanced reworking will ultimately fail unless addressed by a demonstrated career expert in PCB repair. Otherwise, you risk damaging the board or disturbing surrounding components, and this risk is simply too much for most manufacturers to bear.

Another critical issue for manufacturers to consider is the type of rework required. Most in-house PCB manufacturing engineers don’t have the experience or the equipment to rework ball grid arrays or quad flat no leads packages with any degree of consistency.

Handling these components requires specialized training on purpose-built equipment that the vast majority of manufacturers don’t have because they don’t typically need it.

Additionally, PCB reworks such as adding jumper wires, cutting traces, or replacing components are best left to dedicated repair technicians. With the right talent on the job, you can ensure top-quality results and a reasonable guarantee of success. You can even use outside talent to make components with the incorrect footprint fit on a board – something that few in-house engineers would be comfortable attempting.