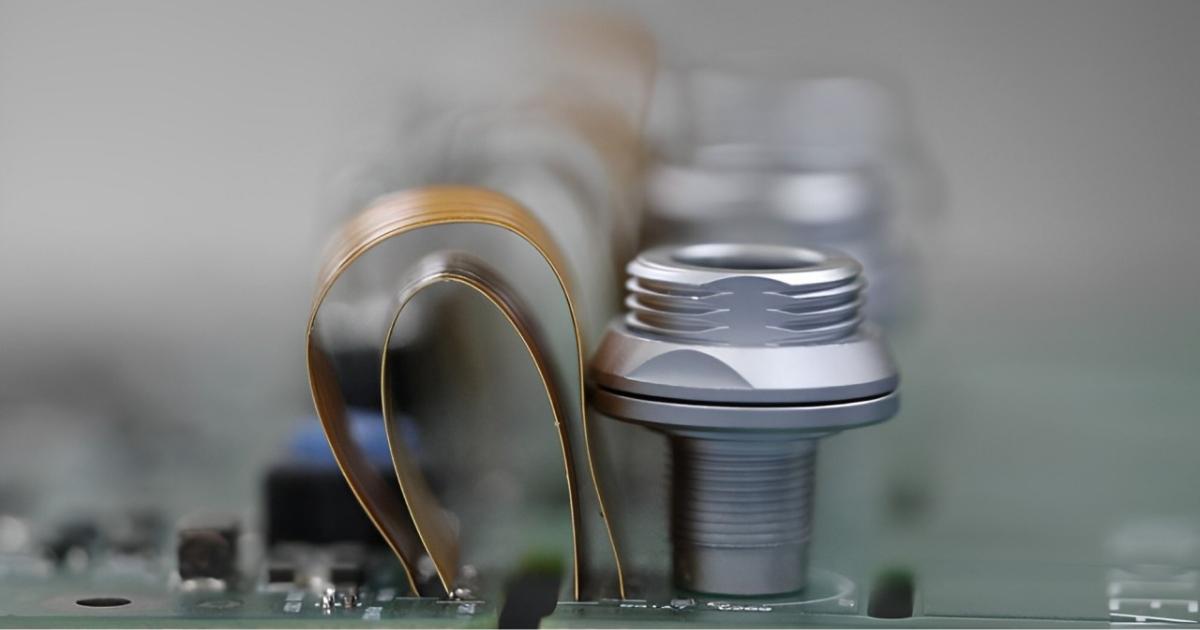

From automobiles and phones to sophisticated military and avionics system and robots, flex circuits are integral to almost every product that we use. The demand for more compact, high performance products and a competitive market has brought flex circuit technology into sharp focus. Product quality, viability, performance and cost all depend on your flex circuit design.

While fulfilling customer needs is critical, success and profitability also depend on streamlining your product design and development process. In our experience, innovative flex and rigid flex circuit design has helped our manufacturing partners gain a competitive edge. With applications and materials continually being designed and developed, the latest technology promises to revolutionize many aspects of electronic circuit design. According to some case studies, it can potentially reduce the total cost of electrical interconnections by up to 70%. Partnering with the right PCB fabrication company makes all the difference.

At Power Design Services (PDS), we have spearheaded unique flex circuit designs to resolve interconnection problems, improved the appearance of and reduced the size of the electronic package and made installation practical and cost-effective. From selecting the best functional configuration, to choosing the proper connectors or components, we can help you fulfill all your application requirements in an economical way. Our cross-industry experience includes solutions for medical device manufacturing, aerospace, semiconductor testing and manufacturing equipment, telecommunications and industrial equipment manufacturers. Hundreds of product development engineers count on our flex circuit manufacturing services to support their product development efforts.

Power Design Services has been instrumental in the development of several ground-breaking products. Notable among these are:

Power Design offers cost-effective single and double-sided flexible printed circuit boards for diverse applications. Industries such as medical devices, aerospace, semiconductor testing and manufacturing equipment, telecommunications and industrial equipment, depend on our expertise for fast and efficient product development. Our turnkey solutions cover your entire project requirements from initial design to PCB design layout review to manufacture/assembly and warehousing. Being ISO 9000, ITAR Certified, assures our customers of circuit quality.

Consult our team about how to improve your circuit designs. We will design a cost-saving flex circuit assembly solution to meet your specific needs.

Request a quote for flex and rigid flex circuit assembly. Call Power Design Services at 408-437-1931 today.

For more information, visit www.greencircuits.com.