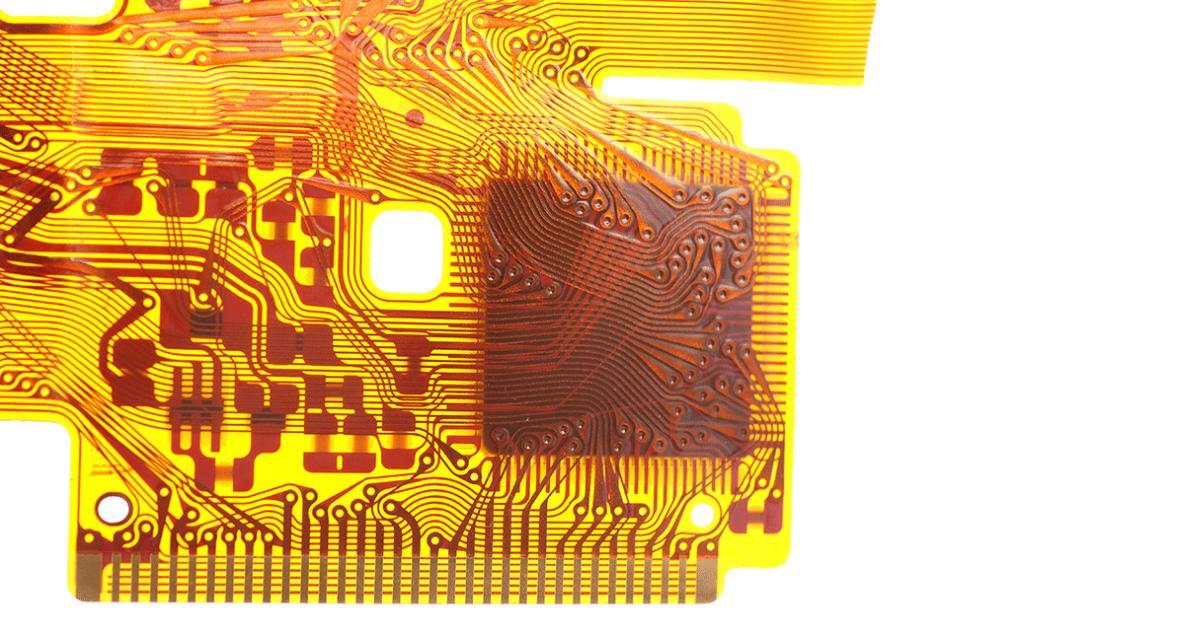

Flex and rigid flex circuits have become increasingly popular in the high-density electronics industry for their cost-saving three-dimensional configurations. The ability to build circuitry to fit the device instead of the other way around, offers significant advantages for complex aerospace, military, and medical device applications.

Green Circuits works closely with clients on their new product development projects and have been instrumental in the development of many new and ground-breaking products such as, Freedom Innovation’s bionic knee and NASA’s micro satellite TechEDSat-X. While there are many benefits to choosing flex and rigid-flex for manufacturer and consumer, the 5 key advantages of flex and rigid-flex for manufacturing innovative product designs are:

Green Circuits is the leading manufacturer of flex and rigid-flex circuits in California and is known for its quality products and 50% faster build times. Green's ISO-9000 and ITAR Certified services are performed in Green's state-of-the-art manufacturing facility to provide you with reliable PCB layout reviews, feasibility assessments, prototypes, quick turns and volume runs to meet your specified budget and time frame.

Green's customers enjoy fast, efficient service with quotes provided in 2 to 4 hours and expedited 24-hour delivery (pick-up and delivery service available for Silicon Valley clients) for time-sensitive projects. . Customers rely on our PCB layout reviews and manufacturing feasibility assessments to avoid the additional cost of rework. Our I verify the quality and reliability of every circuit board before we ship your order.

Contact Green Circuits at 408-526-1700 to talk to a Green expert and learn more about Green's innovative product design and manufacturing services or request a quote.

For more information, visit www.greencircuits.com.