Typically, the most common causes of PCB failures can be attributed to:

Component Design Failure: Incorrect placement of components, power failure, and overheating due to lack of space on the PCB, are just a few examples of things that can go wrong at the design and manufacturing stage. Related Issues:

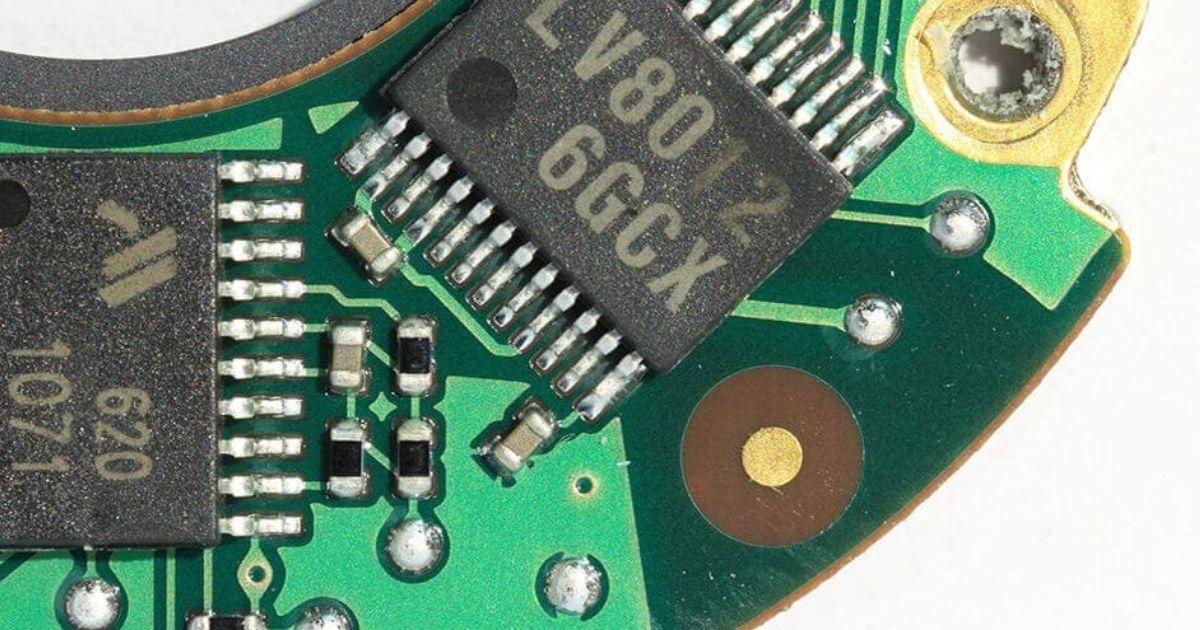

Poor Quality Components: Closely placed traces and pathways, bad soldering to cold joints, poor connectivity between circuit boards, insufficient board thickness, and use of counterfeit components are common examples of inferior PCB quality. Related Issues:

Environmental Factors: Exposure to heat, dust and moisture, accidental impact (drops and falls), and power overloads/surges can be causes of circuit board failure. However, the most damaging cause of premature circuit board failure is electrostatic discharge (ESD) at the assembly stage. Related Issues:

Age: Failures caused by age cannot be avoided, but the costs of replacing components can be controlled by swapping old parts for new ones; which is more cost-effective than new PCB assembly.

A majority of failure issues can be addressed through rework after thorough inspection and analysis. However, the best way to reduce the risk of PCB failure issues is to partner with an experienced PCB assembly company. Our team is more than happy to provide you with answers and a resolution for your product.

If you’re not sure how you would like to proceed and would like additional information, tell us about your project and a Green Circuits representative will follow up with you to discuss your options.

For more information, visit www.greencircuits.com.