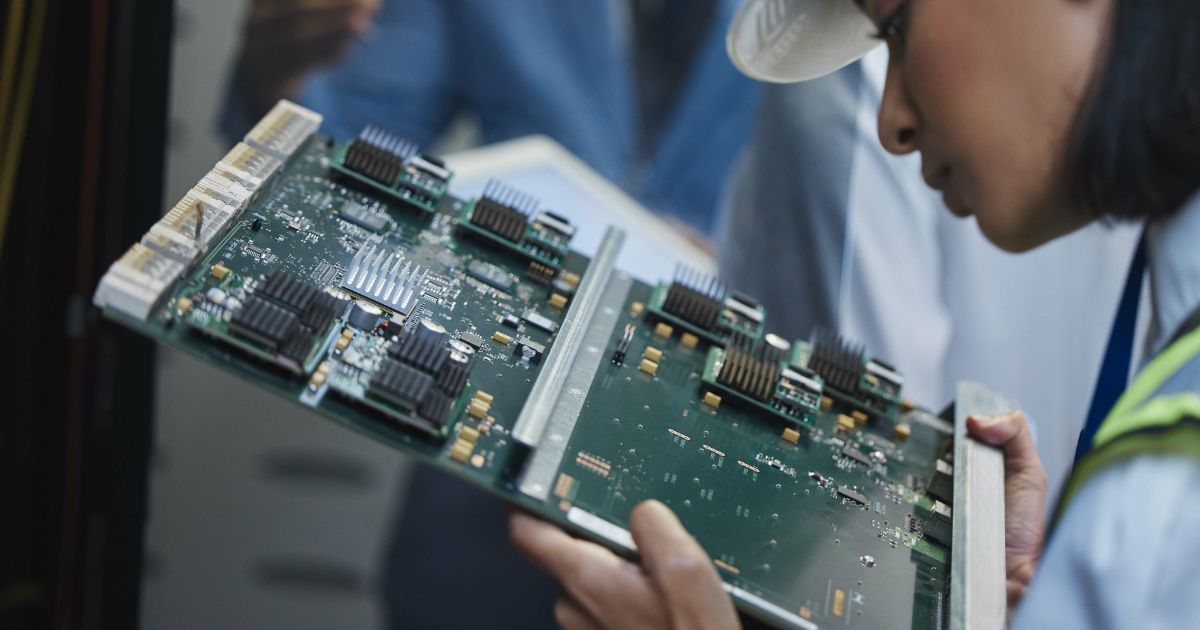

Many, but not all, of the design-techniques for good SI and EMC are overlapping. Taking care of one usually helps the other. One of the essential factors for good and cost effective design is early consideration of these factors, starting already at the concept-phase, through schematic capture and finally designing a PCB. Starting later in the design-cycle usually involves more complicated and costly design (cost will increase exponentially with time), sometimes even wasted board spins and missed schedules. Poor PCB-level or system-level design often cannot be rectified even using elaborate and expensive filtering and shielding methods. Much of that trouble and cost may be avoided by simple early involvement and consideration. Designing for EMC and SI should involve the following main steps:

We can bring expertise in high-speed design to our customers. We can offer review of the specifications and schematics, work with the customer to generate detailed inputs for transition from electrical design (schematics) to physical design (PCB layout, chassis/system considerations). We can also provide guidance and assistance in troubleshooting, and serve as a liaison for obtaining EMC testing, reports, and certificates.